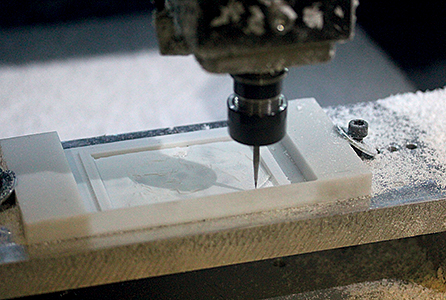

This lithophane of a married couple was created using a CNC machine and Delcam’s introductory 3D modelling and production software, ArtCAM Insignia

Adding depth, contours, and 3D effects significantly enhances the impact and ‘feel’ of signage; modern routers, cutters and lasers provide a plethora of opportunities for innovation and creativity. However, it is the quality of accompanying software that underpins the success of the finished item.

Staying in control

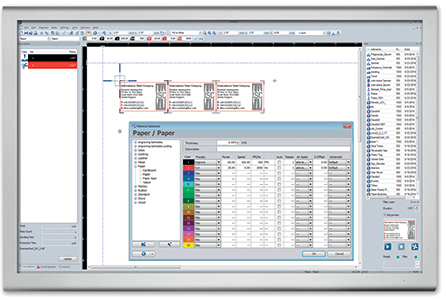

Good software should adapt to the way you work—not the other way round, and JobControl from Trotec Laser has been designed to do just that. It is an intuitive software package that offers full control of all laser functions, assisting users during cutting and engraving.

For smaller jobs in large lot sizes, the design can be repeated within Trotec Laser’s JobControl software at the touch of a button, optimising signage and label production

Sign-makers can utilise their usual graphics programme such as Corel-Draw and optimise the creation process through JobControl’s intelligent design functions. Users can easily adapt the size of their computer monitor to match the size of the laser bed, making visualising the production process during the design stage simple.

With customer productivity as a prime goal, Trotec says it has incorporated a range of user-friendly functions within the software. Job favourites and material databases remember laser settings, reducing the risk of errors when recreating designs of repeat jobs. The photooptimised engraving function ensures sharp engraving results when engraving pictures, perfect for memorial signs and intricate brand logos.

Signage production on Trotec Laser’s intuitive software package JobControl, using Vision and Materials Database

Sign-makers can avoid material wastage with the ‘what you see is what you get’ function with accurate on-screen design representation. For smaller jobs in large lot sizes, the design can be repeated within JobControl at the touch of a button, optimising signage and label production. Bi-directional communication between the laser and JobControl ensures the design will be accurately placed on the work surface and handy guides allow for exact positioning.

Artistic leanings

International design and manufacturing software developer, Delcam (an Autodesk company) provides an array of solutions for manufacturers to create diverse signage systems such as 2D, modular, and back-lit through to complex 3D structures. Its most popular solution amongst sign-makers is its artistic CAD/CAM software range, ArtCAM.

“With Delcam, users are not limited to a particular material or manufacturing process. If a sign-maker wants to laser, CNC machine or 3D print plastic, even gold, they can,” says ArtCAM marketing manager, Rebecca Freeemantle.

If a sign-maker wants to laser, CNC machine or 3D print plastic, even gold, they can”

“Delcam works closely with suppliers so that it has the machining code necessary to manufacture designs accurately. Should software not have the code for a particular machine, the software can save it out in standardised machining code, G code, or a new post-processor can be made.

Delcam’s most popular solution amongst sign-makers is its artistic CAD/CAM software range, ArtCAM, which can be used for a variety of materials and manufacturing processes

“Although ArtCAM 2015 was only released at the beginning of the year, Delcam has announced the release of a newer version, ArtCAM 2015 R2, to give sign-makers greater functionality even sooner. In the release, it is easier to create and work with imported 2D artwork and export it; drag, rotate, and undo parts of an assembled 3D design, and save organic 3D textures for future use,” Freemantle explains. “Additionally relief layers can be saved as part of a group for more complex 3D modelling.”

O Factoid: The design for what would have been the first piece of software was written by Ada Lovelace in 1842 but was never implemented. Alan Turing is credited with being the first person to come up with a theory for software, which led to the two academic fields of computer science and software engineering. O

From a machining side, ArtCAM now allows for knife cutting and more accurate CNC corner machining of slots. Freemantle continues: “What’s more, there are significantly faster machining simulations thanks to a new algorithm that uses the specialist processor in a computer’s graphics card to calculate thousands of operations simultaneously; a vast improvement over standard multi-threading.”

Horses for courses

Robert Marshall, managing director of CNC router manufacturer AXYZ International, offers a resounding endorsement of Delcam software: “In general our A2MC controller will accept a machine program from virtually any CAD/CAM system. Here in the UK we would normally recommend one of the systems from Delcam. These have good general purpose CAD features and have dedicated postprocessors for the AXYZ machines which generate good quality code for fast and smooth cutting.

AXYZ International managing director, Robert Marshall, recommends Delcam software systems for use with the AXYZ A2MC controller, whilst the company offers a number of dedicated CAD/CAM systems, such as PanelBuilder, for other applications

“The Delcam software covers 2D and 3D design and programming and is particularly suitable for signmakers as they handle text very well,” Marshall adds. For other applications, AXYZ has a number of dedicated CAD/CAM systems which are designed for a particular purpose.

“For example,” continues Marshall, “the PanelBuilder software that we supply for ACM panel fabrication has a built in library of panel templates which really speeds up the design process. The system will also automatically nest parts onto a sheet in order to maximise material utilisation and then create the final program without any further operator involvement. In this way large and complex programs which are very efficient can be created very quickly.”

Flexible options

For sign-makers who want the advantages of a software package, without hefty up-front expenditure, Graphtec GB’s subscription-based SAi Flexi software has the potential to provide an ideal solution. Formally introduced at Sign and Digital UK 2015, the latest Flexi sign-making software package from SAi can be accessed online using a choice of monthly subscriptions starting at £14.95.

Phil Kneale, director at Graphtec GB, says that the subscription based SAi software package provides sign and display manufacturers with the most powerful and multi-featured design and production solutions at a fraction of the cost that would normally apply

The software will support a large number of printers and cutters with a wide range of design and production tools that accommodate an extensive range of sign-making requirements, including seamless print-and-cut work-flow and what Graphtec describes as the best vector capabilities within both modules.

Flexi offers a complete solution for printing, cutting, and print-and-cut applications. It will drive up to five printers and cutters simultaneously and includes a raft of production tool options, from colour profiling to Braille and textile applications. Flexi Design is particularly suited to design-only stations. It includes all production enhancements and add-on options as well as being capable of sending jobs to remote Flexi Production Manager, PhotoPrint, or other commonly used RIP software such as VersaWorks, RasterLink, and Onyx.

Graphtec GB’s SAi Flexi software will drive up to five printers and cutters simultaneously and includes a raft of production tool options, from colour profiling to Braille and textile applications

“The package offers a choice of either Flexi or Flexi Design and provides sign and display manufacturers with the most powerful and multi-featured design and production software solutions at a fraction of the cost that would normally apply. It will also deliver a host of additional benefits in terms of performance, reliability and scalability,” comments Phil Kneale, director at GraphtecGB.

Sign and display manufacturers now have access to one of the most comprehensive software packages currently available, with no hefty up-front expenditure”

Kneale expands: “Sign and display manufacturers now have access to one of the most comprehensive software packages currently available, with no hefty up-front expenditure and with the benefit of free access to all ongoing software updates. A trial free subscription is also available, and a clause in the Graphtec GB offer enables subscribers to cancel at any time should they wish to do so.”

It’s a gift

In addition to more standard forms of signage, the use of CAD/CAM soft-ware with CNC cutting machines is enabling sign-makers to diversify and offer something a little different, and the gift market is one area where new opportunities are opening up.

(Above & below) This lithophane of a married couple was machined out of Corian, which is known for its strong and durable properties, using a CNC machine and ArtCAM Insignia software

Nowadays more and more people are looking for something different that will reflect the personality of the person they are buying for and that has sentimental value. This is particularly the case when looking for a wedding gift with a personal touch. Taking a concept from the mid-19th century, the lithophane may provide just the answer.

In essence, a lithophane is a 3D image, carved or etched out of a piece of translucent material. What may, at first, appear dull against a solid background, comes to life when held up to the light, as the thinner areas of material appear white against the light and thicker areas of material, the original material colour.

“This technology has been used to create some stunning pieces, ranging from an array of window decorations, ornaments, lamps and candle holders, to large commercial applications such as interior design for walls, signs, bars and reception desks,” says ArtCAM’s Freemantle.

“Lithophanes are becoming fashion-able again thanks to the use of computer software such as those in the ArtCAM range that can take an image and quickly and accurately convert it into a 3D printed, laser or CNC machined piece of artwork. For example, Delcam’s introductory 3D modelling and production software, ArtCAM Insignia.”

Delcam outlines how it works: To ensure the best results, a high resolution image with a neutral background, ideally a black and white image, is imported into ArtCAM. If the desired photo does not have this or it is grainy, this can easily be corrected in a photo editing package, such as PhotoShop.

From there, users can choose the size of their design or use the photo’s dimensions automatically detected by ArtCAM, so that detail is not lost. All that is then required is to select how deep to cut into the material. Next ArtCAM transforms the photograph into a 3D image by converting the shades of light and dark into varying depths on the z-axis for the CNC machine to cut. Adding a border often helps to not only keep the material strong during machining, but also provides space to clamp down the material if a CNC machine with a vacuum bed is not being used.

To complete the design, the designer needs to select the cutting tools they require to remove the unwanted material from their block of material. Typically using a roughing toolpath developed to quickly cut around the main design areas of the design followed by a smaller cutting tool to add the detail—thus also preventing extended machining times and tool breakages. Afterwards a simulation of the machine piece can be run to ensure that it is as required and the toolpaths sent to the CNC machine.

Whether it is simple engraved lettering or more complex artistic effects you are looking to create, there is clearly a wide range of software, including some with very specific applications, to meet the needs of sign-makers and to provide opportunities to move into new markets.

Your text here...