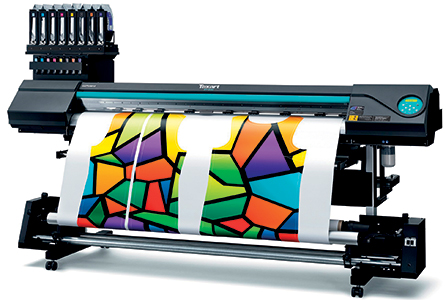

Create high impact soft signage with printed textiles. Pictured: Output from Roland DG’s new dye-sublimation print technology, the Texart RT640

Today’s signage market is changing. Ten years ago, could we have foreseen that dye-sublimation inks and techniques would cause a revolution in our own industry?

I personally first identified textile as a mass growth area when I ran the press office for Sign and Digital UK five years ago—so much so that I took myself off to university and will graduate with a first class honours degree in Textile Design by the time this article goes to press. So here we are now in 2015, with new players on the market and innovation driving growth. I for one believe that this year, direct-to-textile digital printing will come into its own.

Let’s look at the facts: wide-format direct-to-textile printing is just not the same as printing on to paper”

Let us look at the facts: wide-format direct-to-textile printing is just not the same as printing on to paper. For starters, successful digital textile printing relies heavily on matching inkset to the fabric and having the right coating. Finishing and heat processes are also key and manufacturers have to understand the nature of printed fabrics and how they react to treatments in order to successfully bring a new machine to market.

Textile printing on a large scale was not successful in Europe until the eighteenth century, despite the fact that a method for colourfast printing was developed in Europe by 1670. Up until then, everything was done by hand and printing was seen as a threat to the powerful silk-weaving industry. What digital does is allow us to look at these traditional techniques and replicate them in a smaller production environment, without the associated investment of the larger plant.

In this article, I’ve chosen to look at the more recent product launches from Mimaki, Roland DG, and MTEX, who all agree that direct-to-textile printing is a growth area with huge potential.

Expanded offering

Mimaki showcased its new Tx500-1800DS direct sublimation printer at FESPA in May 2014. With a print width of 1850mm and a stated 150sq m/h top print speed, the TX500- 1800DS prints directly to digitally- prepared polyester fabrics, for long production runs. It is well-suited to high quality textile point-of-sale, light boxes, flags, mesh, and all types of soft signage.

The device achieves its productivity levels and flexibility by using six on-demand piezo printheads—which can be specified with four- or six-colour ink configurations—and uses a new fast-drying dye sublimation ink, Sb300. Other features include a degassing module designed to eliminate bubbles in the ink and an auto media feeder with roll-up media capacity of up to 60kg and 300mm in diameter.

Mimaki has also added the JV300 to its range—which is compatible with solvent and water-based sublimation inks, and uses patented inkjet technologies. The water-based sublimation ink produces bright colours and Mimaki say it offers stable printing without uneven colour print results. A key consideration when buying the JV300 or TX500-1800DS is to conduct research into the technology offer—and allocate space for—a separate calendar unit.

“With a Mimaki JV300 plus a calendar and heat press, sign-makers can get up and running with a cost effective, environmentally-friendly solution with an investment of around £40,000 to £50,000,” says Mike Horsten, general manager, marketing, Mimaki EMEA.

Roland re-joins the game

Roland DG has also introduced a new sub-£20,000 dye-sublimation printer in the general price, advising that sign-makers will also need to take into account an investment in a separate calendar unit to start producing textile print.

The company made its official return to the digital textile market with its new Texart RT-640 dye-sublimation printer in October 2014 and the machine will make its UK debut at Birmingham’s Printwear and Promotion show in February 2015.

O Factoid: Textile printing on a large scale was not successful in Europe until the eighteenth century, despite the fact that a method for colourfast printing was developed in Europe by 1670. O

The Texart is compatible with Roland DG’s own sublimation inks, which are available in eight colours including orange and violet.

“One of the Texart RT-640’s major innovations is our new ink. Previously, colours sublimated to fabrics could look distorted with dull blacks, missing greys and fuzzy details,” said Mark Elvidge, print product manager Roland DG (UK).

From sports apparel to flags and contract furnishings, bespoke digital textile printing has finally taken off and Mimaki understand the nuances

He continues: “The RT-640’s variable droplet technology in combination with new Roland Texart dye-sublimation ink displays bold, vibrant colours and rich velvety blacks, as well as subtle gradations and fine details.

“Adding orange and violet inks increases the colour gamut and allows for exceptional reds, oranges, deep blues and purples, while Light Cyan and Light Magenta provide subtle gradations and beautiful skin tones.”

A newly designed Feed Adjuster, combined with a more powerful fan and an included take-up system, ensures added stability for printing up to 32.6sq m/h.

All for one

MTEX Solutions has chosen to develop its own in-built fixation system to remove the need for a separate calendar, a unique feature that is carried across its entire range.

“The single footprint, one pass, one operator model that we’ve developed is one of the key selling points of our direct-to-textile range,” says Stewart Bell, managing director of MTEX Technologies in the UK.

MTEX launched the 3.2m 5032Pro at FESPA London 2013. This Pro model of the original 5032 has a new feeding and take up system, and a new continuous ink feeding system with Epson print heads. The ink is direct disperse and the machine uses a 2l bulk ink system and is destined for high production-led companies.

It prints up to 1440dpi at a maximum speed of up to 58sq m/h as a finished sublimated fabric in one pass. Additionally, MTEX states that this system is able to deliver ‘brilliant and vivid colours’ for applications such as lightboxes, home textile decoration, decotex, flags, sun blinds, window fashion, and automotive decoration.

MTEX has two training centres, one in Porto and one in the UK, ready to help users decide on the best textile printing solution for their needs

MTEX already has 90 machines installed across Europe, including 25 machines in the UK and Ireland. At around £150,000 the price is indicative that the 5032Pro is a serious production level machine, and MTEX has now announced the MTEX Blue for customers more interested in an entry-level machine that offers a professional one-step solution without the need for a separate calendar.

The 1.6m MTEX Blue, aimed at the graphic display market will be seen first at Heimtextil in January and uses Epson DX 7 heads and prints up to 1440dpi in four colours. Although a more entry-level solution at £40,000, it shares the design DNA of its big brother and also offers built-in heat fixation, a 2l bulk ink system, and comes with

an MTEX RIP—which needs to be factored into the overall costing.

Maximising productivity

Whichever option you choose, investing in textile printing involves a large capital investment, so you will really want to hit the ground running and start earning revenue as quickly as possible.

Whichever option you choose, investing in textile printing involves a large capital investment, so you’ll really want to hit the ground running and start earning revenue as quickly as possible”

Roland DG’s Elvidge advises: “Start with your existing clients first. They know you, trust you, and believe in the quality of the work you provide. It’s a great chance to get back in front of them and show them how you are growing and diversifying, which will give them added confidence in you more generally too.

“Get them excited by showing them the wide range of items and materials that can be produced by this technology, how this would enhance the relationship they have with their customers—this is critical to them buying into it. And take the opportunity to ask them what their wish list is. They may have great ideas that are new to you and open up potential new niche sectors for your business too.”

Roland DG’s Texart RT640 dye-sublimation printer has eight colours for a vibrant, wide colour gamut

So introducing textile and soft signage—for that, you can also read ‘replacing the traditional with the innovative’—should be seen as a great step forward in your printing capability and client offering.

However, Mimaki’s Horsten warns though against relying on big national customers: “Companies moving into soft signage will probably find a greater benefit by offering extended product ranges to their existing customers and focusing on local or regional firms rather than targeting head offices of big multiples. Your local shops would probably be happy to pay £50 for a banner that costs you around £20 to produce, but large buyers will really squeeze those margins.”

As far as soft signage goes, MTEX points to the increasing trend for a fast turnover of messages in retail as a particular opportunity for textile. With seasonal promotions and responsive marketing, this means any system that enables a quick switch of graphics will be popular.

“Flags are a high volume market to start with, and they are replaced on a regular basis. This is a happy coincidence as outdoor flags do tend to take a battering by the UK climate, no matter how durable you’re your material is,” explains Bell.

He adds: “The exhibition market is also into textile in a big way and this will continue to grow. But entrepreneurial sign-makers who are open to diversification can also look at joining the growth in customised home furnishings, which I believe will take off in the same way the wallpaper market has.”

Keeping costs down

While the margins in textile printing remain healthy, your return on investment and future sustainability is very much affected by your running costs.

Roland claims its printers are generally recognised for their cost-effectiveness, reliability, and high production capabilities—all of which lead to a strong return on investment for customers over time. They have also invested in the development of their own sublimation inks, and say they are able to keep prices very competitive against other original equip-ment manufacturers and even third party sublimation ink manufacturers.

MTEX also points to consumables as a factor, explaining that its direct disperse, water-based inks do not attack the print heads like solvent ink. They are so confident that they even offer a two-year warrantee on their printheads.

It also claims that the one-footprint model of print and fixation used by MTEX results in cost savings through a major reduction in electricity usage. The advice from the company is that where a rotary heat press will use around 64KwH for about an hour to warm up and then use, an MTEX will use at worst case 11KwH for about ten minutes.

The benefits of fabric

Customers will not just be impressed by the quality of output from today’s textile printers, they will also be happy about the various cost savings and environmental benefits.

Once you have an established fabric tension system, your installation costs for replacement graphics are greatly reduced and fabric is much easier to ship around.

“Even a 3 x 2m graphic can be folded into a small box and sent via UPS, saving time on delivery and reducing your carbon footprint,” says Bell, be-fore adding: “When the ink is impregnated into the fabric rather than laid in top of it, it can be folded and creased safely with no danger of the image cracking.”

Know what you’re doing

Textile printing may look and feel like just another version of wide-format digital printing, but it is no walk in the park, until you understand the nuances. All three of the manufacturers I spoke with, which are just a section of the overall market, confirmed that they have already gone through the pain of the learning curve in order to get to where they are today—in a position to help guide the user in making the right choice for their business.

“While it looks and sounds easy, it’s also easy to make a lot of mistakes with textile printing, and to spend a lot of money but not get the results,” says Mimaki’s Horsten.

He continues: “Anyone considering investing should make sure they really learn about the whole process, and work with a partner who will help them understand the right combinations of machine, ink and the textiles.”

Also worth investigation are the wide range of fabric tensioning and lighting systems for exhibition and display. There are a huge number on the market and certainly worth testing before deciding what is right for your portfolio. And do not forget you will need to invest in a decent sewing solution to make all these products a reality. I have only highlighted three manufacturers in this article, but there are others also trying to carve a niche in this lucrative sign and graphics market place in their various ways with d-gen, Hollanders, Gandy, MS and Epson all offering solutions at different pricing levels and capabilities.

The Mimaki JV300 can take either solvent or dye-sublimation inks. Add a calendar and heat press and a sign-maker has a machine that can cater for core work such as banners, while also being able to cater for soft signage

“Partnering with knowledgeable, helpful suppliers that know the market well will help greatly when it comes to finding niches in the market, assessing additional hardware or suitable and timely media supplies,” says Roland’s Elvidge.

Is it worth it? Honestly, as a busy working mum with two businesses, I would not have gone through the pain of going back to university if I thought it was a passing fad—digitally printed textiles are here to stay, and it is time to jump on board.

ColorBooster pays dividends for Hollanders

Recently receiving a European Digital Press (EDP) award for its ColorBooster DS, and showcasing its 250 model to high acclaim at FESPA 2014, it has been a very good year for Hollanders Printing Systems.

The company’s technology port-folio tops out at the XL 320 model, which provides industrial level of productivity and reliability, and can be bundled with Hollanders in-house fixation technology—the ColorFix and ColorWash XL systems.

One of the star attractions at FESPA 2014 was the ColorBooster 250, as it provides an entry point into the textile printing market at high levels of quality and productivity

One of the key reasons that the DS received the prestigious EDP award is that it is a unique solution for digital textile printing: a double sided printer with an integrated fixation unit.

Described by the company as a ‘one-of-a-kind’ system, it is the first textile printer to include two print engines and a fixation unit, enabling industrial level printing onto textiles on both sides of the media simultaneously. Hollanders says the output is the very highest quality on the market and also offers the best UV resistance. Clever features of the DS include on-board climate control, an in-line media transport, and a remote support system.

“Modularity in our technology is key, as the machines can grow with our customer’s business,” says Hollanders’ chief executive, Jacco Aartsen Tuijn. He adds: “It is a complex process, and so our mission is to help people start their textile printing business. But it must not be too complex, and that is why the design of our printers enable the process to be learnt easily. So you don’t have to have a really skilled operator to get the best out of the machine, it will do it for you and we will help in that process.”

Your text here...