The VUTEk HS100 Pro has been developed by EFI to create a flatbed machine that can produce industrial levels of output without sacrificing quality

There is no denying that wide-format flatbed is becoming the most popular kid in the playground of the sign-making industry, and it is not hard to see why. Flatbed offers sign-makers a wide range of substrates and colour options, high-quality and high-resolution images, quick turnaround time, durability, flexibility, cost saving, environmentally-friendly inks, and the ability to evolve with changing markets. Just glancing around the industry will show that wide-format flatbed printing seems increasingly to be taking over from alternative production methods such as printing roll-to-roll and then laminating. So one must wonder, what does the future hold for this method of printing? Will it replace older production methods entirely? Will it be—or is it already—the sign-makers’ best friend?

The most popular form of flatbed right now comes with a twist—UV light. UV light curing is the magical element of several flatbed system which can allow printing on substrates of even the least permeable quality. Even on common substrates, the advantages are obvious, as the inks are made from acrylics then exposed to this UV light, which results in a speedy turnaround time. Flatbeds are also fitted with an adjustable printing bed, making it possible to print on a range of surfaces, or substrates.

One of the very latest headline launches in this fold is the 3.2m EFI VUTEk HS100 Pro, which can print more than 330sq m/h in production mode and features a range of bells and whistles from the inkjet giant from ‘pin and cure’ technology for maintaining quality at higher speeds, to its use of grayscale print heads.

On the launch of what it claims is ‘market beating’ technology, Scott Schinlever, senior vice president and general manager of EFI’s Inkjet Solutions says: “In this market, printing firms have had to choose between higher quality or higher productivity, but could not get both in a single machine. We have addressed those issues, taking print quality and productivity to a higher level and combining those benefits in the VUTEk HS100 Pro.

“Printing firms no longer have to settle for just going faster; they can have the throughput and high-end imaging they need to make digital the preferred option in an analogue-dominated market for display signage and other applications.”

But what is it about this method of printing that has brought it so much success in recent years? Rob Goleniowski, business manager of sign and graphics, Roland DG, says the reason so many companies have taken up wide-format flatbed printing is because flatbeds include flexibility of output and a reduced work flow.

“Less manual involvement means more time and cost savings,” he says, adding: “Flexibility of output gives users a competitive edge—either they can produce work no one else can, or, if someone locally is doing a flatbed job, then they can compete.”

Flexibility of output gives users a competitive edge—either they can produce work no one else can, or, if someone locally is doing a flatbed job, then they can compete”

It is no surprise, then, that many sign-makers have chosen the wide-format flatbed road. And with success comes progress, so it is no surprise, either, that this technology is continuing to evolve with changing demands.

Roland DG made its first foray in-to the flatbed market with its 64" VersaUV LEJ-640 UV-LED printer, which can also switch to roll-to-roll printing. Using CMYK plus white, and clear inks, it can print up to 13mm thick boards at 4.1sq m/h (1,400 x 1,400dpi) and a top speed of 12.4sq m/h (360 x 720dpi).

Roland DG made its foray into the flatbed market with its 64” VersaUV LEJ-640 UV-LED. The system is a hybrid one and allows sign-makers to also print roll-to-roll

Speaking on the launch of the technology Hiroshi Ono, group product manager for Roland DGA Corp, explained its scope of operation: “As our newest addition to the VersaUV line, the LEJ-640 takes package prototyping and specialty printing to the next level with support for thick media, including corrugated cardboard, foam board and other rigid substrates.

“The LEJ-640 also prints and simulates embossing on virtually any flexible packaging media, as well as on a wide variety of materials used for press proofs, membrane panels, wide-format signage, POP, window displays and interior decor items.”

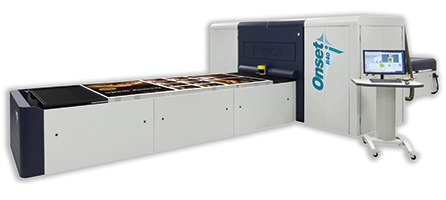

Looking across to one of the original pioneers in this market, FESPA 2014 saw Inca Digital and Fujifilm launch a new flatbed at the top end of the production spectrum—the Inca Onset R40i UV printer. This new printer promises to deliver 80 beds per hour, with a 14pl drop size, and 400sq m/h total productivity. A maximum output resolution of 1200dpi can be produced on media up to 3.14m x 1.6m (123.6 inches x 63 inches), and up to 50mm (2 inches) thick at the rate of up to 80 full-bed sheets per hour. Users can also reduce their labour costs and increase productivity, thanks to the printer’s continuous feed and print feature.

The Inca Onset R40i UV flatbed printer was demonstrated for the first time at FESPA 2014

The R40i is a clear example of technology to adapting to businesses’ ever evolving production needs. With such models, businesses will find that as they grow, customers can change elements of the printer, such as the UV curing lamps, automation, speed modes, electronics, and software.

Heather Kendle, Inca Digital’s director of marketing and product management, says the R40i delivers the ideal combination of speed and quality for companies, producing a mix of fast turnaround retail graphics for distance viewing, but also producing high-quality graphics for short distance viewing.

She says: “The beauty of the Onset Series, which now features a choice of twelve different models and three different handling systems, is that print companies can not only pick exactly the right Onset with the right combination of productivity, quality, and ink options for their business, but also evolve their machine to meet their changing needs whenever they wish.”

Previously, the Onset Series launched the S50i flatbed, which was the first to be developed on Inca’s new-generation Onset Scaleable Architecture. It was designed to satisfy the market's growing need for greater productivity, and the customer’s desire for a greater level of personalisation, combined with shorter run lengths, giving users the ability to choose the best printer for their initial requirements, with flexibility to change productivity levels and ink options as their business evolves.

Substrates and beyond

Beyond speed and efficiency, the wide-format flatbed also offers sign-makers a wide range of features which enhance diversity of the final product, in terms of substrates, colour options, and quality.

The most obvious area for diversity is in the range of substrates the flatbed can print on, for as long as it has a flat surface and can fit into the maximum printable area, you can print on any material, to any size, and any shape.

Oriol Gasch, category manager at large-format sign and display for HP Americas, says this diversity of substrates will only see flatbed capabilities growing in the future: “What’s growing are specialty applications using diverse and unique substrates, such as ceramic, metallic, glass, and other thick, heavy materials,” he says, adding: “Also, printing on corrugated board for pack-aging is an increasing market, and either primary or secondary packaging for impulse purchases. A unique item is wine boxes.”

What's growing are specialty applications using diverse and unique substrates, such as ceramic, metallic, glass, and other thick, heavy materials”

The range of colour options has also evolved, with sign-makers able to choose from bright and opaque white, which the Flatbed Mimaki JFX 500-2131 LED UV offers, to metallic silver. In addition, flatbeds like the Agfa Anapurna M2540FB (45sq m/h top speed, 17sq m/h at 720 x 1440dpi photographic mode) and the Fuji Acuity Advance Select HS hybrid (60sq m/h top speed, 21.1sq m/h at 1,200 x 1,200dpi in fine art mode) also provide sign-makers with a stepping stone into this valuable market sector.

LED UV-curing flatbeds such as the Mimaki JFX500-2131 offer a greater range of colours such as bright and opaque white and consume some 75 percent less electricity

Thanks to the use of UV light curing systems on many modern flatbeds, the technology can also boast durability in the final product. Because UV light is used instead of heat to cure the ink, images are not only instantly dry, but will not come off if they get wet.

The Agfa Anapurna M2540FB provides a key entry solution into the dedicated flatbed printing market, providing a robustly built solution that is both cost-effective and still able to output top-quality graphics

As the icing on the cake, for the environmentally-conscious sign-maker, flatbeds could be the greener choice. With the UV drying system in place, there is no need to use harmful solvents, and because images are printed directly onto the substrate, no vinyl waste is produced.

Looking ahead

So what does the future hold for wide-format flatbed printing? Roland DG’s Goleniowski believes that lower prices in the future would mean that the investment would become more viable for companies, while specialist inks would open up more market opportunities for suppliers.

However, he says, flatbed printing will not replace other forms of print production: “There are still many reasons why a print and cut machine, for example, may be more versatile and profitable than a wide-format flatbed printer. Both machines are application specific, so both have strengths and weaknesses, depending on the job. This makes them good complements, not alternatives.”

The Acuity Advance Select HS Hybrid printer from Fujifilm has a top speed of 60sq m/h in production quality mode and 21.1sq m/h in fine art mode

Tudor Morgan, systems marketing manager at Fujifilm Graphic Systems Europe, says the technology that went into making these printers had moved tremendously over the past few years.

“In the future, I think we will move more towards 3D printing,” he says, adding: “I think there will also be more combinations of digital and LED printing, so you will have an image that may have some texture, and then that image will be enhanced by movement. I also think the economics of flatbed printing—the speed, software, and cost—will come down in the future. They will also become more reliable. Flatbed printers are a very powerful part of the industry.”

It seems everyone in the industry is interested in wide-format flatbed printing and where it is heading, so much so, that FESPA themselves have launched a survey on the phenomenon.

The survey, which was announced at FESPA Digital back in May, will take the form of a census, and will be the broadest and largest global research initiative ever to map the wide-format print community, aimed at gathering comprehensive data about this community—its size, business performance, growth prospects, and key areas of development and investment.

The census consists of 30 questions for printers to complete either online, or face-to-face at any of FESPA’s global exhibitions and events between now and the end of the year.

The data will then be analysed by independent industry research organisation InfoTrends, and a full report will be issued at FESPA 2015 in Cologne, Germany.

FESPA general secretary Sean Holt says as the leading global organisation representing the wide-format printing community, it was vital that FESPA had robust information about the community and insights into the economic, structural, technological, and social forces that were shaping it for the future.

O Factoid: One of the earliest known wide-format flatbed inkjet printer was manufactured in the mid-1990s by a company named Data Mate. This printer was called the Rembrandt and used printheads from Sharp. O

“With the FESPA Print Census, we aim to significantly expand the base of respondents to give us the truest possible global picture,” explains Holt.

He continues: “We are targeting a minimum of 2,500 respondents which will allow us to provide statistically robust information on national, regional, and global level.”

Holt adds that the data derived from the census would be invaluable intelligence for FESPA’s members: “It will help them to benchmark their own business with others, to gauge their performance against industry norms, and to see to what extent trends in their organisations are reflected elsewhere.”

But, even a year before the results of FESPA’s print census are released, it is clear to see that the wide-format flatbed phenomenon has taken the industry by storm. In the broad scheme of things, it was not that long ago when people had never heard of inkjet printing, and now the industry is saturated with this new technology that is not only flexible, but has also reduced manual involvement, and, probably most importantly, has the ability to evolve. Perhaps, then, wide-format flatbed printing in its latest guises really is the technology that will transform today’s modern sign-maker.

Your text here...