Smaller machines, such as the Roland CAMM-1 GS-24 desktop cutter, are very portable and can be used for on-site modifications or production, if required

From the production of decals and stickers, to window signs, floor graphics, and many other applications, vinyl cutting machines have firmly established their place as a standard piece of kit in the vast armoury of sign-making equipment that is used today. Whether for small intricate items or large scale pieces of work, the range of possibilities continues to grow.

To find out more about the advantages of purchasing the latest automated vinyl cutting technology and the new sectors that can be opened up for sign-makers and print-service-providers, I talked to some of the key manufacturers and suppliers in this field.

A solid investment

The general consensus is that vinyl cutters represent a solid investment, with many advantages to be gained. “Vinyl cutters have always been a good investment and usually pay for themselves very quickly,” says John de la Roche, national sales manager at Hybrid Services. He adds: “They are very durable devices and are often subject to hard labour for ten years or more in the field; and when they eventually do need replacing most sign-makers are keen to reinvest to ensure vinyl cutter operation in their business.

“Investing in a cutter, such as those offered by Mimaki, is inexpensive. In addition, media is cheap, plentiful and available in lots of colours and textures, which opens up a wide variety of applications. The systems are easy to use and, with some basic training, anyone can easily produce and fit stunning graphics.”

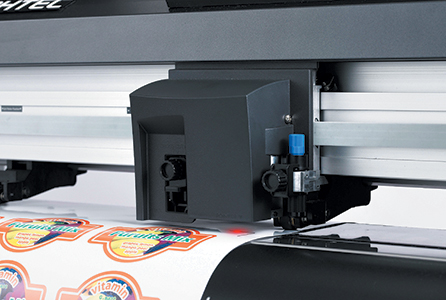

Mimaki’s Half-Cut function produces a series of half and die-cuts, leaving a few connection points that keep the image in place, so that the sticker or image can be easily pressed out, or the complete sheet or roll can be sent to the customer

Graphtec GB director, Phil Kneale, agrees: “A vinyl cutter represents arguably the most versatile and powerful production workhorse currently available to the sign and graphics industry; and, when used with a compatible digital printer, it also offers one of the most cost-effective and reliable print-and-cut solutions for this industry.”

Rob Goleniowski, head sales for Roland DG (UK) also takes the view that vinyl cutters offer a low-cost way to add extra production capacity to a business.

A vinyl cutter represents arguably the most versatile and powerful production workhorse currently available to the sign and graphics industry”

“You can keep your main printer to do the higher volume jobs and let a vinyl cutter do the little extra ones that you’d normally say you didn’t have time to do,” he explains.

“There is a lot of cut vinyl work about, so investing in a vinyl cutter is a very affordable way to get a business started,” continues Goleniowski, adding: “Additionally, smaller machines, such as the Roland CAMM-1 GS-24 desktop cutter, are very portable and can be used for on-site modifications or production. Vinyl cutters can also be used for packaging/cardboard mock-ups and nests.”

Alex White, managing director of Blackman and White, adds: “Investing in a vinyl cutter can be a great move for a sign-maker, as the right machine can help them move into markets where larger and more complex logos and designs are needed, such as decals and vehicle wrapping.”

Broadening horizons

When it comes to the new avenues that vinyl cutters can lead to, our experts are again in accord with each other, citing the wide range of materials now available as a further factor in opening up new opportunities.

“Vinyl cutters can help businesses diversify into loads of different sectors, including garment personalisation, vehicle window tinting and pin-striping, sandblast and stencil/paint-mask films, general vinyl signage, floor graphics, window graphics and glazing films, and much, much more,” comments Goleniowski, who emphatically adds: “The list of applications is almost endless, and limited really by the creativity and imagination of the user.”

De la Roche observes that, while cut vinyl for vehicle graphics has been a very popular use for cutters for many years, Hybrid Services has seen an increase in retail, exhibition, point-of-sale, and floor graphics from cut vinyl.

“Over this time, lots of different materials have been developed for more specialist applications such as garment transfer, frosted glass windows, carbon fibre, wood effect, reflective high visual, chrome, pearlescent, and many more,” explains De la Roche, who continues: “So that, with experience and knowledge, sign-makers without a digital printer can now easily compete for most commonly requested graphics.”

Graphtec’s Kneale expands on this point: “To an increasing extent, sign and graphics manufacturers are now using vinyl cutters, originally installed primarily for core production requirements, to open up new markets and introduce additional revenue streams. For little or no fresh investment, sign and graphics companies are now engaging fully with other market sectors and in particular the print wear and promotional products, digital printing, labelling and packaging industries, all of which offer a huge potential for diversification, future growth, and profitability.”

He continues: “A vinyl cutter can also be used to process a much wider range of materials than was hitherto possible. These include flock and flex, cotton and polyester for garment production, customisation and decoration, sandblast stencils employed for stonework, and rhinestone applied to sport and leisure wear and fashion accessories. Additionally, vinyl cutters can be used for the creation of special effects and the production of all kinds of soft signage such as banners and flags.”

Kit and caboodle

With the range of vinyl cutters currently available, from small desktop models to wide-format, it can be a daunting prospect, for both those at entry-level and more established businesses, to decide which machine will serve them best. Looking at their own product ranges, our experts offer their advice.

Goleniowski recommends the Roland CAMM-1 GS-24 desktop cutter as a lower price, entry-level option for businesses looking to invest but with a smaller budget, or who do not need the width of a larger cutter.

“With a smaller width than the CAMM-1 GR series, it is ideal for signage, garment decoration, and labels applications—and much more,” he remarks.

Goleniowski advises further: “For the larger business, our latest generation CAMM-1 GR series of cutters are packed with advanced features, including USB and network connectivity as standard; dual blade positions for kiss cutting and perf cutting; fastest performance in class; two year warranty; and a very sturdy build and great reliability. They are ideal for businesses looking to invest in amazing value for money vinyl cutters that offer great flexibility in terms of the materials they can cut—from normal self-adhesive vinyl right through the thick materials like motocross films and everything in between.”

For start-up graphics companies De la Roche believes that the entry-level desktop Mimaki CG-60SRIII, which comes with a two year warranty and Fine Cut software, is a superb option.

Hybrid Services recommends the entry-level, desktop Mimaki CG-60SRIII, which comes with a two year warranty and FineCut plug-in software, as an ideal option for start-up graphics companies

Alternatively, the CG-FXII series high specification wide-format cutters feature an optical eye for perfect print and cut registration, free Fine Cut plug-in software, stand, roll holders, and USB interface for fast data transfer.

“Mimaki’s unique Half-Cut function produces a series of half and die-cuts, leaving a few connection points that keep the image in place. When the job is done the sticker/image can be easily pressed out, or the complete sheet or roll can be sent to the customer,” states De la Roche.

Mimaki CG-FXII series high specification wide-format cutters, available from Hybrid Services, feature an optical eye for perfect print and cut registration

With over 50 years of experience, Graphtec GB has brought to the UK market a number of significant solutions developed by Graphtec Corporation in Japan. Among the most notable of these are the recently rebranded CE6000 Plus and the newly upgraded flagship FC8600 series of roll-fed cutters, the latest FCX2000 series of flatbed cutters, and the new F-MARK automatic digital die-cutting system.

The Graphtec CE6000 Plus series is now available with new and enhanced features to enable significantly increased levels of productivity and is one of the most popular and cost-effective cutting solutions for entry-level users

“The renamed CE6000 Plus is now available with new and enhanced features to enable radically increased levels of productivity and remains arguably the most popular and cost-effective cutting solution for entry-level users,” maintains Kneale.

The cutter has a maximum cutting speed of 1,000mm/sec (exclusive to the

CE6000 Plus 120 model) and a cutting force of 300gf (increased to 450gf

on the CE6000-40 machine). Key features include the Graphtec ARMS

(Automatic Registration Mark Sensing) facility, tangential emulation,

and a perforation cutting facility. The CE6000 Plus is also supplied as

standard with Graphtec Pro Studio software.

“For higher productivity levels, the recently upgraded FC8600 series of

cutters is ideal; and it claims ‘fastest in class’ status with a maximum

cutting speed of 1,485mm/sec and a cutting force of 600gf,” Kneale

affirms.

The Graphtec FC-8000 series cutters incorporate the latest version of Graphtec’s ARMS system which uses sensors to detect registration marks and performs the axis alignment

The cutters incorporate the latest version 6 of Graphtec’s proprietary ARMS system and the ISM (Intelligent Scan Mode) function and are supplied as standard with the latest Graphtec Pro Studio software. This is based on the popular Flexi Sign family of design and production software developed by global leader SAi.

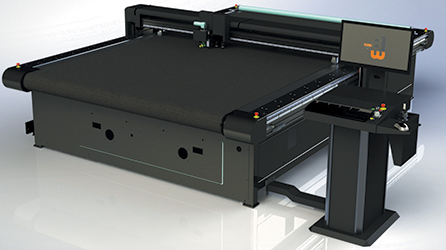

The latest FCX2000 series of flatbed cutters includes a specially configured cutting head incorporating two tool holders, both of which enable cutting with the second also providing a creasing function and drafting with a pen.

The latest Graphtec FCX2000 flatbed cutters includes a specially configured cutting head, incorporating two tool holders, both of which enable cutting with the second also providing a creasing function and drafting with a pen

These cutters also incorporate version 6 of Graphtec’s ARMS facility.

Finally, the relaunched F-Mark combined automatic sheet feeder and

digital die-cutter is based on the widely specified CE6000-40 cutter. It

is available in a choice of three sizes (920 x 610, 920 x 1,800, and

920 x 1,800mm) and the option of either a vacuum suction or

electrostatic material hold-down facility. The former is ideal for the

processing of heavier and thicker materials, while the latter is better

suited to lighter-weight media such as vinyl.

Graphtec GB’s recently relaunched F-Mark combined automatic sheet feeder digital die-cutter is one of the products that, for very little or no additional investment, enable sign and graphics companies engage with other market sectors, such as print wear and promotional products, digital printing, labelling and packaging industries

“The cutting systems Blackman and White manufactures here in the UK lend themselves to printed vinyl and our state-of-the-art camera and associated software can calculate distortion and cut logos even up to 20 to 30ft long,” asserts White, who continues: “This includes cutting to registration marks on more challenging media such as both non-reflective and reflective materials, including 3M diamond grey automotive, which is popular for police cars and signage.

Blackman and White suggests its Genesis range as a good base for sign-makers to start from with its wide range of functions and fast return on investment

“Thanks to our multi-tool heads we’re able to offer through cutting and kiss cutting, ideal for masked vinyl or multiple layers of coloured vinyl to keep more complex letters and logos together, at high speeds up to 2m per second. Our Genesis range on the other hand would be a good base for sign-makers to start from as they offer incredible functionality with a very fast return on investment.”

Our state-of-the-art camera and associated software can calculate distortion and cut logos even up to 20 to 30ft long”

Indeed, the conveyorised model offers the flexibility to cut long panels of vinyl on a rotating cutting bed, which is less labour intensive with increased production speeds. The conveyor system also has a small footprint for optimising floor space.

“For those sign-makers perhaps looking further along the line and wanting to diversify their products even further, there’s the Versa-Tech, which offers all the benefits of the Genesis but with the addition of a routing facility, which vastly expands the range of media and applications sign-makers can work with,” White adds.

He concludes: “Being able to offer clients a range of complementary signage for different applications, and having that little something extra special in their ‘back pocket’ to offer that other companies can’t, can really make a difference.”

O Factoid: More than 125 years ago, US company Eastman introduced the first electric cloth-cutting machine for the garment industry; in the late 1960s another US company, Gerber, developed a numerically controlled machine for accurately cutting large stacks of cloth. Both of these are forerunners of the CNC vinyl cutters we know today. O

From this brief guide to the whys and wherefores of purchasing a vinyl cutter, it is clear that, for a reasonably small outlay, sign-makers and print-service-providers can open up a whole new vista of business opportunities. A further plus is the fact that getting to grips with the technicalities of the equipment appears to be relatively easy, even for novice users.

What is more important to note is that, just because this is a mature sector, it does not mean the technology has stood still. The systems described and highlighted above are a big step forward from a decade ago, and even when compared to two years ago have important upgrades and advances that increase productivity, efficiency, and the quality of the end product. If you are working your current work horse hard every day, or have the ambition to grow your business in this sector, then it would be well worth your time booking some product demos with your own files to put the latest kit to the test. Or alternatively you could visit the upcoming Signlink Live and its co-located sister event The Print Show from October 11th to 13th, where all the companies listed above will be on hand to not just talk the talk, but walk the walk.

Your text here...