Precision cutting: complex shapes can be cut out using the latest in computer controlled machinery, such as kit from Zund

Computer numerical control (CNC) machines are the product of decades of intense research and development that has fueled a revolution in industries across the world. Before CNCs, cutting out letters, shapes, logos, and motifs was largely done by hand, either by knife or on cutting machines with a limited flexibility. The mass production of logos, for instance made out of layering vinyl, was a laborious and time consuming process.

With the advent of both Macs and PCs in the late 1970s and early 1980s, Gerber introduced the first automated cutter and since then the range has grown exponentially, due the ever-increasing capacity of computer technology linked to CNCs.

All the traditional techniques of engraving, cutting out intricate shapes, grindings, slicing, drilling, and routing can be replicated at the touch of a button, or rather a keyboard. Now, smaller sign-makers can produce large amounts of signage very quickly and economically, which has inevitably led to a mushrooming of the industry as now the potential range of customers is vast.

As good as the operator

CNC machines are used in the sign industry to cut out shapes, etch, rout, grind, and print a wide range of materials from textiles to metals, and from wood to vinyl. However, it is up to the operator who inputs into the computer to make the most of the CNC machine as, like all kit, it is simply a tool.

Computer control: the operator can use precision graphics on screen while overseeing the cutting table close by

There a wide range of CNCs used in our industry, beginning with desktop models for a few hundred pounds, rising to major pieces of kit taking up large amounts of floor space for tens of thousands. Choosing a machine clearly depends on your budget, but perhaps more importantly what type of work you need it for and the quality that is desired.

Before splashing the cash, it is worth spending time checking out the various machines available and visiting or talking to sign-makers outside of your area. Potential competitors will not be keen, but someone at the other end of the country who presents no threat will probably be more help, and will give you some of the pros and cons of their CNC.

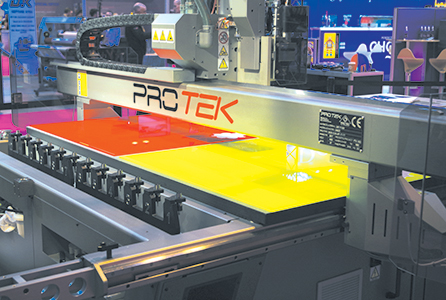

A Protek cutter in action at this year’s Sign and Digital UK exhibition on the Complete CNC Solutions stand

Once you have got a good cutter, you can also take on associated work such as shop fitting. Speaking about this subject, Steve Ward of Merlin Tools in Loughborough, says: “We supply solid carbide routers and all the collets and holding equipment for the routers. The sign-making industry is becoming more and more high tech so everyone is investing in CNC cutting equipment for their routers.

The sign-making industry is becoming more and more high tech so everyone is investing in CNC cutting equipment for their routers”

“We’ve also seen a cross-over developing between sign-making and woodwork for shop fitting and interiors for retail and offices meaning some sign-makers are not just making signs but also moving into producing a full package for clients.”

Quality of the cut

One of the main aspects that separate the different sizes and capabilities of being able to cut to size substrates is the quality of the cut and how the blade is engineered and fitted.

It may not just be blades as there are laser cutters that do the same job as Gareth Lewis of Think Laser in Redhill, Surrey, explains: “The advantage of our Light Blade laser machine over a traditional CNC cutter is that you can do far more intricate work, so you can bring in graphics and engraving designs into the machine’s software. There’s no wear and tear on the parts or the blades so nothing is going to wear out as the laser beam will continue to be the same throughout the time no matter what happens.”

An important tool to think about as an additional accessory to your CNC cutter or router is a board cutter

Think Laser’s Light Blade series of machines are developed and designed in England, and then manufactured in China. They are not suitable for metal or heavy-duty materials such as stone, but are ideal for lighter substrates such as paper and card, and feature software that allows for both off-line and on-machine job creation and artwork importation, along with parameter set up and control. All models are supplied with closed loop water cooling, creating greater stability from the laser output.

Meanwhile, Austria-based Trotec also produces high specification industrial laser cutting machines; its SP series flatbed laser cutters are designed for cutting plastics, wood, and textiles. Again, like Think Laser, they cannot cut metal or stone, although they can engrave them—so some of the substrates used in sign-making, such as steel and stainless steel or a mixture of man-made and ferrous metallic combinations, are not suitable for laser cutting machines.

There are a number of manufacturers of cut to size machines that can handle extremely thin or thicker substrates, and this is where prices and specification matter. Essentially, the more the work is intricate, or needs either thick or thin structures, up goes the specification and price. Machines made by firms such as Yamazaki Mazak, DMG Mori, GF Group, Tekcel, Protek, Kimla, Zun, Bisse, AG/CAD, DYSS, Canon, and more will be on show at Signlink Live in October.

Wall-mounted cutters save space and can help you reduce waste by allowing your production department to only process what they need on a CNC device

Shaun Firth of manufacturer Biesse says about the company’s laser cutters: “The Rover Plast is the largest machine in our range and it’s a machine used for cutting plastics, acrylics, non-ferrous metals, leather, and vinyl. It is a very versatile machine for the sign industry and is a very compact machine.

“We have 25 customer service people and helpdesk individuals in the UK to support our customers and to give them peace of mind at all times. We are the leading technology in the world in CNC machines with more than 4,000 employees to support the products and our customers.”

Cutting with a blade

Roland DG has a range of kit including large-format printer cutters, vinyl cutters, and UV printer cutters. The company says its large-format digital printer family includes a, “range of technologically advanced, yet user-friendly, colour printers and printers/cutters designed to suit the varying needs of graphics and signage professionals”.

The firm is best known for its wide-format printers, but also offers cut to size cutters to create large-format signs, vehicle decals, stickers, heat transfer apparel, and window graphics with units such as the ACMM-1, GR-640, GR-540, and GR-420. They are designed for faster cutting using increased down force including perforated cutting on materials that are up to 42" wide.

Another manufacturer is the longstanding German company Aristo, which was one of the first manufacturers of flatbed plotters for cutting sign-making vinyls. As sheet material or from the roll, with an automatic material advance system for continued cutting of overlong jobs, kiss cutting, or diecutting, their adapted tool-heads, laminates, heavy vinyls, or special materials such as Diamond Grade reflecting vinyls are good for general sign-making.

O Factoid: With the advent of Macs and PCs in the late 1970s and early 1980s, in 1981, Roland introduced its first CNC model. O

As you check out the various machines, the terms ‘kiss cutting’, ‘down force’, ‘steppe motor loop’, ‘tangential emulation’, ‘overcut’ and ‘guaranteed tracking’ will be used by those selling or demonstrating the kit. Do not be confused, as they all help to describe the capabilities of the cutter. It is also good to know what the difference between servo control and digital is, and what the implications are for the machines.

Kiss cutting is the ability of a cutter to make a light cut around each sticker in a sheet so the sticker can be peeled off individually from its original backing sheet. It is important to have a cutter that keeps the material flat and rigid as well as have the sensitivity of the kiss cut capability. Down force is how hard the machine presses the blade down into the material to successfully cut it and it will vary depending on the substrate with metals needing more than say, vinyl. Overcutting is the ability of the cutter to go past the point of finish such as in a circle to ensure the item or graphic is separated from the rest of the material and the cut is complete.

Material handling

If you plan to cut very fine or very thin films for heat transfer or other delicate applications, then you will need a cutter with superior material handling, which means a cutter with significant downforce to hold the material steady.

These cutters will have a digital servo control operating in a closed loop meaning the cutter is always making adjustments for position feedback to control its final motion and position. It makes the movement of the cutting head more accurate and also the movement of the roller that feeds the material through the machine. Cheaper models will use a steppe motor operating in an open loop.

These do not feedback to the cutter, but rather break the cutting process into small movements known as a steppe motion. These machines are fine for larger more basic vinyl graphics, but are noisy to operate and do not have the capability to do fine work as the blade is not continually adjusted and will drag around corners and curves.

Likewise, for thicker films and vinyls, a digital-driven motor is the way to go as the steppo system will tend to wear out quicker and not give the finish required.

Also important to note is the tangential emulation feature, which relates to the angle of the blade when cutting a circle or a curve and whether it dragged around a corner without changing its angle or is adjusted for the new angle. Every blade has an angle and an offset, and in cutters where there is the tangential emulation feature, the cutter will adjust the angle of the blade by picking it up and turning it at high speed before lowering it back at an adjusted angle so it does not drag on the material but cut through it cleanly.

Moon Shine: delicate engraving on wood

To do this, quality software is needed as well as a good machine. Without software, there are limitations, so it is important to have software that is designed to work with the cutter so as to read files generated by printer RIPs or graphic software, identify printed registration marks to align cutting perfectly to print, and to split longer jobs up into manageable sections.

Complete CNC Solutions, which distributes Tekcel routers is one of the most well known names in the world of routers and is something of a fixture at the annual Sign and Digital UK show at the NEC. The firm says the latest routers provide knife cutting, creasing, engraving, and incising tools.

Julian Sage, managing director of Complete CNC, says: “We’ve developed an unbeatable range of cost-effective tooling products, specifically designed to deliver high quality routed-edge finishes, across a wide range of materials for the woodworking, joinery, exhibition manufacturing, and shop-fitting industries. We are always available to lend expert advice and knowledge for customers requiring help when choosing the correct cutter, feed rate or machining strategies for CNC routers.”

A cutter is only as good as the blade, these are from Merlin Tools

Meanwhile, a lot of sign-makers will also have a wall-mounted cutter to cater for larger signs. They can make a lot of sense if you are also moving into shop and office fitting work where large amounts of MDF, vinyl, and plaster board are required along with Perspex and even glass. Sign-makers will often say that they also save space in workshops chock full of kit and supplies.

Wall-mounted cutters should slice through foam board, aluminium, and corrugated plastics, and feature laser sight line guides for cutting pre-printed graphics. Some wall mounted units are also freestanding, making them easier to reposition when the workshop is rearranged.

Then there is the issue of vinyl cutters. Speaking to Signlink, Phil Kneale, director of Graphtec, says: “As a key part of the sign-maker’s armoury, vinyl cutters enable companies to engage with new markets as diverse as the print wear and promotional products, packaging design, labelling, and digital printing sectors whilst helping close the gap between traditional sign-making and these sectors.

“There are now many sign and graphics companies, invariably two- and three-person operations, moving conspicuously into, for example, the potentially lucrative print wear and promotional products sector on the basis that 90 percent of the equipment installed for core manufacturing activities can now be adapted, with little or no additional investment, to create new market opportunities and introduce a vital new revenue stream to fuel business growth and commensurate profitability.”

Cutting has come a long way from the days of basic machinery in the 1970s when hand and eye skills were the priority. Turning around larger jobs of cut vinyl was a slow and cumbersome operation, but with the advent of computers in the 1980s, that has all changed. For a few thousand pounds, cutters are an essential weapon in a sign-maker’s toolkit, and if you get the right machine, you can undertake work that you would normally sub-contract out, thus keeping the work in-house and increasing profits.

Your text here...