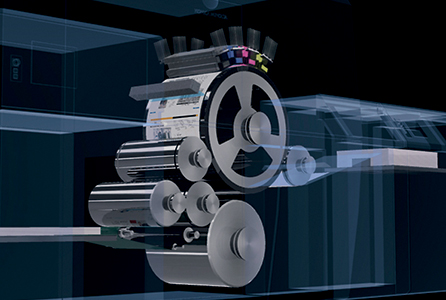

Inkjet printing has been described as a ‘highly stable printing platform full of opportunities’

2016 is the year of the journalist. Whether it be the EU referendum or Murray winning Wimbledon, tragedy in France or devastation in Iraq, military coups or the Chilcot report, the press has not been short of a powerful headline at any point this year.

The political events of the last two months in particular have left even the most stoical among us reeling. And whether you support Britain’s exit from the EU or are against it, it cannot be denied that the uncertain times we live in make running a company even more of a delicate process. Nobody is entirely sure what our country faces, and in the face of such insecurity the need to exercise caution is at the forefront of most business leaders’ minds.

O Factoid: Political and economic uncertainty is affecting those at all points on the wealth spectrum. Women’s champion of Wimbledon, Serena Williams, received a $2.63m (£2m) payout that had been worth $2.97m (£2.3m) before the plunge in value of the pound after the Brexit vote. O

In such an uncertain climate, then, how can manufacturers persuade their clients to make substantial investments in technology? I spoke to key figures in the high-volume inkjet sector, to see if one can possibly justify parting with this much capital in times such as these.

Spend money to make money

Unsurprisingly, the answer is a resounding yes. While of course preaching caution, manufacturers and suppliers can still find convincing arguments for the benefits of technological investment—and perhaps now more than ever.

For sign-makers used to wide-format inkjet technology, these smaller page sized cousins are a major step up in terms of productivity and product scope, but, and its a big one, they could allow you to tap into a rich seam of profits by cross-selling everything from brochures to point-of-sale sigange to your current customer base.

First with words of reassurance is Mark Hinder, head of market development at Konica Minolta Business Solutions Europe. He explains: “Inkjet is a highly stable printing platform that brings a new world of business opportunities for customers. The technology that we have developed has been designed to show a return for many many years and will be highly suitable for our customers who are constantly seeking new innovations.

Inkjet is a highly stable printing platform that brings a new world of business opportunities for customers”

“Our systems are highly productive print systems delivering new value applications to a market which is now again valuing print for all that it can deliver. It’s exciting times for those printers working with brands who want to lead innovative personalised campaigns by using a wide range of new stocks, such as heavy textured, which perhaps they couldn’t choose because of the limitation of their current technology.”

He continues: “One of the major steps forward has been the development of HS high viscosity inks, which is another reassurance to customers on their investment. These inks are very special and allow us to produce stunning results on a wide range of media without any pre-coat, maximising the savings from using standard offset stock. Inkjet will also be the bridge between offset and toner moving forward creating the new high volume industrial print platform.”

In terms of continuing to invest in yourself, Konica Minolta is leading by example, as Hinder explains: “This is a sector with huge market potential. We are totally committed to inkjet and have created a new specific business division to help our customers with the technology. It’s a sector in which we will continue to be a major player and grow our offerings accordingly through leadership, innovation and partnerships.”

Invest in quality

These sentiments are shared by Robert Holscher, director of digital sales at Komori International Europe, who explains the business benefits of investing in a high-volume inkjet press: “The quality of inkjet is outstanding and the use of UV ink has very big advantages with use of material and instant dry prints. The most important development in this sector is the combination of speed, quality of print, and the ability to do this on a wide variety of substrates. Developments from Komori are focused on printing on any material without precoating or priming.”

Robert Holscher, director of digital sales at Komori International Europe, says the most important development in the high-volume inkjet sector is the combination of speed, quality of print

Since Drupa 2016, Komori has offered the new Impremia IS29, a high-volume B2 inkjet press able to print with UV ink on any substrate up to 0.6mm thick, with a speed of 3,000 sheets per hour.

In addition, at Drupa the firm demonstrated the B1 Impremia NS40 with Landa technology, which prints on material up to 0.8mm thick, at a speed of 6,500 or 13,000 sheets per hour.

Holscher continues: “The Impremia IS29 is suitable to run at constant high production with different materials, even plastics without precoating. The high end RIP enables companies to produce variable data print at these high speeds, and there is no reduction in speed due to material or size.

Since Drupa 2016, Komori has offered the new Impremia IS29, a high-volume B2 inkjet press able to print with UV ink on any substrate up to 0.6mm thick

“The highest quality combined with the production speed and UV ink makes the Impremia IS29 ideal for the short-run, high-end productions. The IS29 can easily run 400,000 B2 sheets a month and is capable of perfecting.

Other machines do not provide perfecting capabilities in this segment.”

Also eager to promote the capabilities of high-volume inkjet equipment is Robert Corbishley, European/UK PR manager for Xerox. He comments: “Fast digital inkjet presses can offer print service providers (PSPs) a number of advantages, including unprecedented turnaround even with very large jobs. The burst capacity of some of these presses dwarfs even the fastest toner presses by some considerable margin.

“The very nature of the presses being full colour means that print service providers can take advantage of simplicity and improved cash flow. No more requirement to pre-print offset shells weeks or months in advance with capital being tied up and no more requirement to pulp when a company letterhead changes enabling a true white paper factory model to take place.”

He continues: “Xerox’s unique High Density (HD) ink lets PSPs typically use the same uncoated, untreated plain offset or laser papers they are already using, eliminating the requirement to use more expensive inkjet treated papers, without having to pre or post-coat the paper while at the same time offering a large gamut with very limited show-through. This means customer facing documents are vibrant and eye-catching whilst at the same time offering extremely comprehensive ink volume and resolution controls delivering a better ROI for the PSPs.”

Protect your investment

Another approach in encouraging clients to spend is by focusing on the longevity and reliability of said investment. Corbishley of Xerox, explains: “Many customers tell us that they want inkjet presses to last, maybe up to ten years. Think about where technology was ten years ago in print and you can see the great steps forward in computing power so imagine where it will be in the next ten years.

“At Xerox we believe investment protection is a cornerstone of our inkjet families and this is why we offer upgrades to existing presses. Some three years ago we introduced HD ink, we offered it to all of our customers and most took advantage of what it offered. This year we announced a 30 percent speed upgrade was possible on all existing presses, customers are able to take advantage of this. We also announced a new print server to enable even faster job RIPping, and again, our existing customers are able to take advantage of these upgrades so they are not left trailing behind as enhancements appear.”

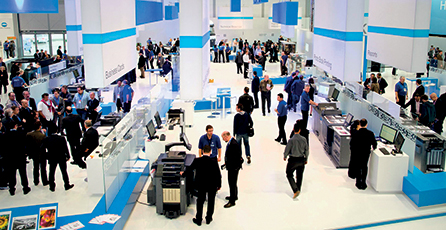

For its customers interested in inkjet investement, Xerox hosts the Impika Inkjet Innovation Center, located in Aubagne, France

He continues: “An investment in an inkjet printer needs to be considered in terms of what it can offer businesses. It also needs to be implemented as a complete solution, looking at the end to end workflow (or even the entire document lifecycle) to best understand where the economies are truly to be made.

“Printing typically accounts for a maximum of 20 percent of the entire operation, so savings made there can quickly be lost by inefficiencies or additional expenses elsewhere. Xerox works very closely with customers to understand the influences outside of the press to ensure the very best solution, right sized to customers’ needs. We also seek to increase automation through robust integration, while still retaining that ability to offer flexibility for today and scalability for tomorrow.”

Continuous feed presses on offer from Xerox include the Impika Evolution (up to 254 metres per minute) and the CiPress 500 (2050ipm 2-up duplex A4, 152 meters per minute), while its cut sheet range includes the Brenva HD Production Inkjet Press (197 A4 sized images per minute) and the iGen 150 (150 PPM).

Face the future

So, while the future of the country (and perhaps the world at large) is becoming increasingly hard to foresee, can we provide any solid predictions about the inkjet sector in the years to come? One of the first places to start when looking at upcoming activity in the industry is, of course, trade shows, and this year’s Drupa is no exception.

Amongst the enormous variety of technology on display was Konica Minolta’s AccurioJet KM-1, as Mark Hinder explains: “This eagerly-awaited B2+ UV inkjet press, was launched at drupa. On our booth at the show it was performing in combination with MGI’s Jet Varnish, showing visitors a wide range of benefits. They include moving short-run offset to digital inkjet, the ability to carry out hybrid printing with the integration of KM-1 into existing offset processes, duplex printing on larger sheet sizes as well as ability to print on packaging board, lightweight papers and textured stock.

Amongst the technology on display at Drupa 2016 was Konica Minolta’s AccurioJet KM-1, the firm’s new B2+ UV inkjet press

“One major step forward was our demonstrations at Drupa involving alliance partners Tharstern and Vpress on how we can integrate highly automated workflows and cloud-based technology—including JDF—into the AccurioJet KM-1 Inkjet Manager. Another major development involved showing a new integration of Kodak’s Prinergy Workflow with our Accuriojet KM-1 high speed B2+ sheet-fed UV inkjet press at drupa. The integration delivered an advanced level of control for Accuriojet KM-1 users shown live on our drupa booth.”

Fujifilm and Heidelberg’s new B1 format inkjet printer, the Heidelberg Primefire 106, was unveiled at Drupa 2016 to a packed crowd

One key event at Drupa for those in the high-volume inkjet world was the unveiling of Fujifilm and Heidelberg’s new B1 format inkjet printer, the Heidelberg Primefire 106. Fujifilm’s inkjet technology will work together with Heidelberg’s developments in press manufacturing and system integration capabilities, with the aim of achieving quality output comparable to offset with superior consistency and reliability. The new machine will be driven by the Heidelberg Prinect Digital Front End (DFE) to optimize workflow and quality.

The Heidelberg Primefire 106, created in partnership with Fujifilm, was shown in prototype at Drupa and is now moving on to beta testing

The machine, which was shown in prototype at the show and is now moving on to beta testing, could be an example of the future of the sector, as Gerold Linzbach, chief executive officer of Heidelberg, explains: “In record time, Fujifilm and Heidelberg have jointly developed the world’s first B1 truly industrial inkjet digital printing press. Our original partnership was based on a joint evaluation of Fujifilm’s core inkjet technology, and after two years of co-development, we remain convinced Fujifilm is the best partner.”

Commercialisation for the new platform is planned in the latter part of 2017, by which time Britain may have left the EU, Scotland may have left Britain, and Donald Trump might be president. What an interesting time to be alive.

Your text here...