Direct-to-object printers are allowing sign-makers and print-service-providers to produce personalised items such as bottles, phone cases, and t-shirts that are unique to each customer

If you walk the halls of exhibitions such as Sign and Digital UK or The Print Show, you are sure to see plenty of freebies from personalised pens and notepads to t-shirts and phone cases. Before even looking at the innovative technology available on the market, this clearly demonstrates the impressive capabilities of printing equipment today—able to print directly onto even the most complex of objects such as keyrings, headphones, and beauty packaging.

Set to debut at this year’s Sign and Digital UK is Mimaki’s most recent addition to its UJF range, the UJF-7151 Plus. Stuart Cole, national sales manager for industrial products at Hybrid Services, Mimaki’s exclusive UK and Irish distributor, comments: “This industrial production level flatbed offers a solid and powerful digital alternative to traditional screen printers, with a 710 x 510mm print area, on-demand printing of the very highest quality and the capacity to print objects up to 150mm thick.”

Mimaki’s new UJF-7151 Plus can print objects up to 150mm thick and is ideal for adding value to branding items

Mimaki’s small-format LED UV flatbed UJF series includes printable primer, white, and clear ink options. Cole adds: “The A3 UJF-3042FX and HG (High Gap), along with the larger, A2-sized UJF-6042 offer the capacity to print onto rigid substrates up to 50mm and 150mm thick respectively, with stunning print quality and terrific adhesion to a multitude of different substrates.”

Stuart Cole, national sales manager for industrial products at Hybrid Services, says ‘quality is the predominant factor affecting the market as personalised and bespoke products naturally come under close scrutiny by the

end user’

Alongside this, Mimaki’s 8 by 4´ (2.4 x 1.2m) JFX200-2513 and JFX500-2131 LED UV flatbed printers, can print onto unusual surfaces such as glass and slate, and includes a wide choice of inks including white and clear.

Resolute DTG brings a unique machine to the market which can be used to produce braille. With advancements in the technology, the machine can print braille onto even thin substrates like aluminium, plastic or even self-adhesive vinyl.

Colin Marsh, managing director of Resolute DTG, explains: “We sell a UV direct-to-substrate printer called an MVP. This is available in five different sizes for different kinds of work. Where the MVP is unique is that it can actually do textured printing which has a raised texture and is one of the only machines in the world that can do digital braille which is ADA compliant.

“The textured printing ranges from small areas of text that can be raised to images that automatically pick out raised areas. If you’ve got a picture of a lace up shoe, the laces can be raised as texture. It can be an easy thing to do but it’s very effective, especially on phone cases. It’s in effect variable data embossing and is the only machine that can do that. It’s also a cylindrical printer so can print glass, aluminium, and plastic bottles as well.”

Resolute DTG uses environmentally-friendly ink, Zero VOC, which Marsh explains does not give off any odours which means the machine can be used in a closed environment.

The ValueJet 426UF from Mutoh is an A3 plus flatbed printer which boasts impressive environmental credentials. Melanie Enser, Colourgen’s marketing manager, comments: “The inks are LED-UV so everything is cured onto whatever your object is—coasters, keyrings, pens, glass, anything you want. LED-UV ink is generally better in terms of environmental footprint; it does give off more heat though as you’re curing the ink to the substrate. The levels of energy consumption are not too different to other printers but during printing it uses less than 330 Watts, which is quite low.”

The ValueJet 426UF from Mutoh, supplied by Colourgen, is a compact printer that can sit on your desktop and print on substrates up to 2.75? (70ml) thick

Enser notes that the applications possible with the ValueJet 426UF are broad, from a company that does the cabling at Heathrow, to the souvenir market, and even for personalised condoms. She adds: “For a pretty low investment, you can do all sorts of things now, you just have to use your imagination.”

For a pretty low investment, you can do all sorts of things now, you just have to use your imagination”

Roland DG recently expanded its portfolio with the VersaUV LEF-300, which can print onto acrylic, wood, plastic, fabric, and leather. Using a primer, the machine can also print onto glass and metal.

Joe Wigzell, academy and creative centre manager of Roland DG, explains how the machine works: “When 3D items are placed on the flat table, an automatic height adjusting function amends the position of the table until its surface reaches the height most suitable for printing. This ensures accurate printing across a wide range of objects varying in sizes including: pens, mobile phone cases, signs, personalised awards, giftware, industrial goods, and product prototypes. For smaller items, the LEF-300 features an added benefit of a vacuum table, which holds lighter items securely in place while printing, keeping production in alignment and ensuring the final print is accurate.”

Joe Wigzell, academy and creative centre manager of Roland DG, says the VersaUV LEF-300 is ‘the perfect workhorse for both short and long production runs that require high productivity at low effort’

Roland DG also makes bold claims in the machine’s speed capabilities. Wigzell continues: “The easy-to-use machine is the fastest UV printer yet with four print heads and two UV-LED lamps allowing bi-directional printing onto items up to 100mm in height and 8kg in weight. As well as an unrivalled print speed, the LEF-300 requires minimal set-up time and streamlines the printing process; making it the perfect workhorse for both short and long production runs that require high productivity at low effort.

O Factoid: The VersaUV LEF-300 from Roland DG has a print area of 770mm wide by 330mm long, and can print onto objects 100mm in height and 8kg in weight. O

“The LEF-300 also features two channels each for both white and clear gloss inks to accommodate faster printing and increased density of gloss. When applied in multiple layers, the advanced ECO-UV inks can mimic embossing and 3D textures to create a huge range of artistic and special effects to add a premium value to the produce and increase profit margins.”

Roland DG hope the machine will ‘bridge the gap’ between high volume printing and short run customisation jobs in one versatile machine.

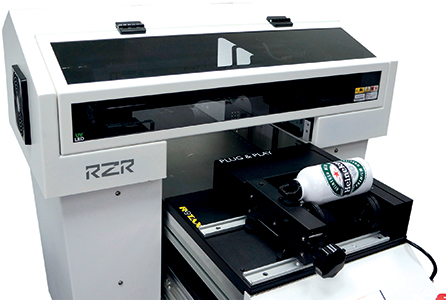

Croatia-based Azonprinter, a manufacturer of digital printing solutions, also recently showcased its latest solutions at FESPA Digital in Amsterdam including its ‘plug and play’ Rotax system for bottle printing. Rotax allows printing on a broad range of cylindrical objects with a diameter ranging from 41 to 127mm and up to 279mm in height.

(Above & below) Azonprinter from Croatia has developed Rotax for bottle printing, and with a new rotary adapter it can print even more varied applications

A statement from the company says: “With a new rotary adapter, it is possible to print more varied print applications. Print on cylindrical and cone objects such as beer and wine glasses, cups, candles, tube, cans, tanks, vases, awards and much more. The revolutionary and innovative way of printing on anodized aluminium opens new business opportunities for potential customers.”

Make it personal

Cole of Hybrid Services believes the personalisation sector has seen ‘massive growth’ but that the market is more ‘broad-based’ than you would think. He says: “Mimaki’s unique ‘Kebab’ option opens up the world of cylindrical printing direct to bottles, candles, tins and much more. Now with the introduction of the Mimaki UJF-7151 Plus offering top-end quality, Mimaki’s direct-to-object hardware offering really is an entrepreneur’s dream.

Resolute DTG’s MVP printer is cylindrical so can print glass, aluminium, and plastic bottles as well as braille signage

“The capabilities for personalisation go way beyond printing to promotional merchandise and we’re seeing an increasing number of bespoke direct-to-object applications including localised slate placemats, wedding invitations with exquisite texture and one-off glass splashbacks. The opportunities are limitless.”

The capabilities for personalisation go way beyond printing to promotional merchandise and we’re seeing an increasing number of bespoke direct-to-object applications”

Marsh of Resolute DTG also sees the growth in personalised gifts as developments in technology have enabled products to get better and better. He says: “The direct-to-substrate market is growing very, very quickly because of a lot of companies producing online personalised gifts. Because this is variable data and there’s no set-up, you can hook a website straight into the RIP software so the printing is fairly automated with very little labour cost involved.

“It’s very important that a machine can produce a wide range of substrates, the modern UV inks can print onto practically anything. The previous version of inks had adhesion problems so the print would peel off the item, but now it does adhere to them well.”

Enser from Colourgen agrees that personalisation is key in today’s market, commenting: “Personalisation, I think, is very important as it’s such a big thing in every area, for example, personalised cards that you can send off for, t-shirts, cakes, it goes on and on. It is certainly an area which is really growing.”

Wigzell of Roland DG similarly says that customisation is crucial for staying competitive. He says: “In today’s highly saturated market, customisation is now deemed key to remain ahead of the competition and with the VersaUV LEF-300, it is easier than ever to create premium bespoke products.

“The direct to object printing capability gives print professionals the flexibility and competence to provide digital, personalised customisation with minimal set-up procedures and optimum output. This combination allows for highly accurate printing at a low cost when producing both high quality one off items and batch customised products; resulting in high profit returns for businesses without comprising on quality.”

Market drivers

There are many trends in the market that are pushing technology forward. In the direct-to-object printer market, Cole of Hybrid Services believes quality is key. He says: “Quality is the predominant factor affecting the market as personalised and bespoke products naturally come under close scrutiny by the end user, maybe for a special occasion that requires a high-end look and are often items that are seen up close.

“The impact and effect of the print also depends on the material being printed to, and Mimaki’s introduction of printable primer gives adhesion to a very wide range of materials to give the wow factor, and this diversity is definitely another driving factor in this sector.

“There’s also a great process of education going on at the moment, whereby people are starting to understand the tremendous potential available to them through direct-to-object printing and we’re seeing a surge in creative applications being produced with Mimaki printers.”

Marsh of Resolute DTG cites personalisation as the top trend pushing the market forward: “Online personalisation has to be the number one trend affecting the direct-to-object market. There’s massive potential with a very low cost as instead of stocking items ready to ship, everything is printed on the fly on demand. It’s a very simple, quick process.”

Enser of Colourgen points out the benefits of personalisation in a competitive market and believes customer demand is pushing for more unique items. She says: “There’s more and more demand for personalisation because it’s a way of differentiating yourself in a tough market. The more you can print something that’s a bit different and the more you can produce something that is unique, the better.”

Wigzell of Roland DG discusses the time and cost saving benefits of direct-to-object printers: “The direct-to-object printer application streamlines printing processes by eliminating the need for printing onto labels and then transferring onto the product. This gives our customers the added value of removing unnecessary print phases, saving money on both time and costs, and giving print professionals access to new and exciting opportunities. Smaller businesses are able to expand product ranges, and explore unique ways to remain competitive and adapt with the ever evolving market.

“The trend for highly creative bespoke items will continue to grow over the next year and so for Roland DG customers, having a machine that can enable them to print directly onto virtually any item will give them the upper hand to their competitors.”

After speaking to manufacturers of direct-to-object printers, it is clear that gaining access into this sector of the industry is easier than ever before, with more versatility with substrates, faster printing times, and easier to use machines. With personalisation agreed across the board to be important in today’s industry, direct-to-object provides sign-makers with a valuable business opportunity to generate profit.

Your text here...