Complete CNC Solutions prides itself on being able to provide technical solutions for the demands placed on the modern sign-maker for ever-tighter turnarounds and exotic fabrication materials

For many sign-makers, the path to success means meeting customers looking for output that involves the cutting of resistant materials such as plastics, wood, and metals. The good news is that the revolution in computerised routing means the availability of systems capable of cutting, engraving and even shaping such materials with ease and speed. Modern systems are able to force lots of different materials into creative alliance and add enormous value to readily available, inexpensive stocks.

Choosing and getting to know a computerised routing system is not without its potential pitfalls and getting it wrong could be costly. Thankfully there is a rich selection of machinery available and—provided you pick a partner that knows what he is doing—great support to help you get the most from your new asset.

The wholesale swing toward digitally printed output has pulled along increased demand for systems that are capable of an additional level of print finishing. With so much output being adhered, or printed direct, to rigid substrates—that are subsequently cut to shape—many companies are taking tentative steps into cutting rigid materials. There is a very wide range of suppliers and technology developers in this area with different balances of cost to performance ratio and specialisations.

In addition those explored below, names like Zund, Biesse, Colex, Blackman and White, Multicam, and Vision are just a few of the players in the UK. And so to really drill down into the sector, it is perhaps worth looking at a representative cross section that have focused their efforts on the signage market.

Some Sage advice

According to Julian Sage, managing director of Complete CNC solutions, the initial interest rapidly develops into something much bigger: “The logically indicated route to go if you want to profile-cut digital output is for a lightweight film cutting system that can handle an equally light router spindle. We have no end of people telling us that such a purchase very quickly runs into the buffers of its own limitations as these systems typically do not have appropriate material holding capabilities and can’t handle waste extraction.”

Sage continues: “We strongly suggest that the time to take the next logical career step into rigid cutting is when you take the first. Go for a capable router right away. It won’t cost any more than a fully tooled-up light-weight and it will do so much more.”

Go for a capable router right away. It won’t cost any more than a fully tooled-up lightweight and it will do so much more”

The advice comes from the head of a company arguably well placed to offer it. Complete CNC Solutions has sold, and now supports, hundreds of Tekcel systems, which are working hard and earning their keep for their owners. The company claims its systems have features that allow them to power through the toughest resistant materials including plastics, wood, and metals. On the other side of the coin Sage emphasises that the technology is still able to handle more delicate substrates like films, paper-based products, fluted boards, and foam plastics.

A typically configured Tekcel router from Complete CNC solutions has a number of key tools and key pieces of technology that come as standard. For example, Sage explains that the machine bed features a cupped vacuum hold-down system and t-slots for improved production accuracy and efficiency. This is not something that might mean much on demo-day, but weeks into the ownership period when the real needs of the system are dis-covered, it really makes its difference felt. It also means the system can confidently handle any material, size, and shape that comes its way.

The Tekcel Exr from CNC is configured and ready for sign production, including a tools rack, machine bed with a cupped vacuum hold-down system, and T-slots. The design means any size or shape of materials can be processed without lengthy setup time

This flexibility is also backed up by build quality according to Sage, and the Tekcel routers are indeed large and impressive looking machines. So, to think that a simple component of the system that weighs less than an ounce is the ultimate determiner of the quality and speed the system can accomplish comes as a surprise to many, but that is absolutely the case.

Sage explains: “We’ve invested more hours in developing tooling suited to the materials our customers cut than I care to remember but I don’t regret a second of it. Today, we can offer Tekcel owners—or anyone with a computerised router—a brilliant range of cutters for all applications. One router owner who only started buying our premium ‘cut-polish’ single flute cutters recently came back and said it was like the whole system had been upgraded. It really does make that much difference.”

Sage goes on to emphasise that many sign-makers venturing into cutting rigid materials in-house find them-selves in very alien territory and that Complete CNC has structured its support facilities to, ‘make the journey as simple as it can possibly be’.

Tekcel Routers also feature auto-mated tool-change, application specific extraction, and waste extraction systems that are built to cope with industrial workloads. This is facilitated with 8kw spindles that, while capable of moving large tooling through resistant materials, are still controllable with a degree of finesse that makes dealing with precision-cutting operations using delicate materials possible. Rigid machine construction and durable, high-precision ballscrew drives, coupled with ‘intelligent’ software drivers, also help impart immaculately finished cuts. The end result is no evidence of mechanically introduced aberrations in the output, which ultimately means less manual finishing and more money saved.

Capable of complex, multistage processing and production, Tekcel routers also feature proprietary control systems that are easy to operate and reduce the need for manual operation. In addition to camera-assisted tangentially-steered cutting, Sage advises that everything is simplified: indexing tool-lengths is automatic, work clamping is versatile, and production is fast, clean and accurate. He further advises that Tekcel router range has been broken down into a number of configurations and sizes to handle needs that scale from entry-level to industrial.

The Esko route

For those at the entry-level stage, Esko has extended its Kongsberg finishing product line with the Kongsberg V series entry-level digital cutting system. Promising to deliver reliability, precision, and ease-of-use, the Kongsberg V series incorporates standard configurations for sign and display applications. The company claims that although entry-level in price, the systems are built to the same robust standard as the rest of Esko Kongsberg’s technology.

“The addition of the V series extends our family of digital cutting solutions to make them accessible to companies who need an entry-level cutting solution, but who do not want to compromise on quality, precision or reliability,” comments Paul Bates, regional business manager of North-west Europe at Esko.

The Esko Kongsberg V series is available in two standard configurations and the Kongsberg V for signage and display, and the Kongsberg V for packaging. The former features the MultiCUT tool head for vision-controlled cutting and routing. This system combines all tool insert options with an air-cooled milling spindle up to 45,000rpm, which Esko claims is perfect for a wide range of sign and display materials including acrylics and other synthetics. The camera system and innovative front-end soft-ware make it the perfect solution for production of lower volumes of signs and displays.

The Esko Kongsberg V-Series Router is an entry-level system designed to allow sign-makers to bring heavier sign fabrication and finishing in-house

The Kongsberg V for packaging is specially configured for sample making, short-run production of mockups, and other packaging-specific applications. This could open up a profitable revenue stream for sign-makers who can offer this service as part of a wider project for customers. For example, if you have been tasked with producing all the signage for a new retail outlet, you can offer to produce packaging samples and mock-ups before they go into full production.

The system incorporates a FlexiHead, which the company says offers, ‘highly accurate, powerful cutting and creasing’ of packaging material such as folding carton and corrugated board. The FlexiHead is also attached to a very precise servo axis controlling the tool depth when cutting, creasing, and routing. Further to this, three configurable tool stations accommodate a full range of standard tool inserts.

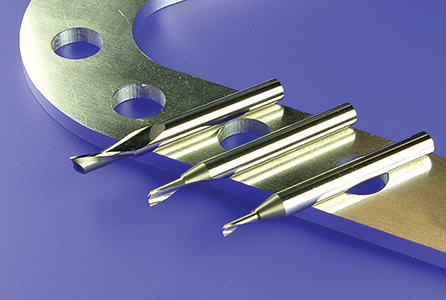

The need to cut metal accurately and cleanly is a daily must for the sign production department. Tekcel offers a wide range of bits to suit different applications

Testing of the new family began in Asia last year as Bates outlines: “It was clear that there was a global need for a high-end digital finishing solution at an attractive entry-level price. We believe they are perfect for customers who want the productivity, reliability, and precision that is characteristic of Esko Kongsberg machines for specific applications.”

It was clear that there was a global need for a high-end digital finishing solution”

The Kongsberg V series is available in two sizes; V20 and V24, and is able to work on material with sizes of 1700 x 1300mm and 1700 x 3200mm respectively. There is also a broad selection of tools, allowing it to cater for a wide range of cutting, creasing, drilling, and plotting activities. Market tried and tested features also include the i-cut Vision Pro camera system for accurate print-to-cut registration, even with print-distorted materials. Esko claims that exchanging tools is, ‘quick and error-free’ because every insert is identified by a unique bar code and easily snaps into place. Insert knife tools are available for cutting materials ranging from thin paper and synthetic sheets to heavy-duty packaging and display materials. And the rack-and-pinion drive system balances raw power with the finest axis control, ensuring speed, durability, and strength.

O Factoid: The most sophisticated computerised routing systems can only perform as well as the cutting tools installed in them. Single-flute cut/polish tools in premium solid carbide provide the best finish on all popular plastics used in sign manufacturing and have a long tool life, which lowers the cost of operation. O

The Esko Kongsberg product family includes the Kongsberg C series, which recently collected an EDP Award for ‘Best Large Format Finishing System’. The large-format tables are designed for higher productivity output and can finish a mixture of 3.2m wide, flexible and rigid materials. The range also scales up through the X series with options for versatile production requirements, heavy-duty and continuous operation, as well as fully automated systems.

Easy as AXYZ

One of the UK’s core technology developers in this area, the routers now supplied by AXYZ International have a host of recently introduced machine upgrades designed to further enhance their performance capabilities. Arguably, the most important of these is the ‘Auto Zone Management’ (AZM) facility, which ensures the material being processed is always held securely throughout the production process to provide optimum accuracy and clean finishing. AXYZ report that in addition to ‘greatly enhancing material hold-down efficiency’ the system virtually ‘eliminates material wastage and machine downtime’ caused by incorrectly set vacuum valves.

The 4010 Router from AXYZ is a work horse of the industry, and has provided a large number of sign-makers with their first stepping stone into the market

Further to this, the AZM facility supplements and now supports other performance-enhancing machine up-grades according to AXYZ. These include the latest A2MC machine control systems which reduces ‘bounce’ and vibration caused by sudden acceleration or deceleration, frequently found with other control systems. The ‘Vision System’ is also integrated with the A2MC system and is compatible with all of the cutting tools used on AXYZ routers. The tools include oscillating, tangential, and drag knife cutters to enable a much wider range of materials to be processed.

A further optional machine upgrade is the latest helical rack and pinion drive system that is designed to greatly reduce machine wear via the system’s multiple gear teeth configuration. AXYZ says this also ensures a more even distribution of the workload, which in turn results in increased feed rates, greater accuracy of cut, quieter machine operation, and ultimately longer than normal machine life.

The AXYZ 24-hour online CNC-Routershop division has also been recently expanded with the introduction of both UK and overseas-sourced new routing and cutting options. These accommodate not only the requirements of AXYZ and Pacer routers in the AXYZ International portfolio, but also virtually any other make of machine regardless of type and country of origin.

Two heads is better than one: AXYZ has a number of industrial spec routing solutions for those who want to hit the big time, or even become a trade finishing supplier

For such an apparently mechanical solution, the modern router is much more digitally-based and therefore more accessible for the modern sign-maker. The other key factor is that demand for graphics printed directly to rigid substrates has been increasing year-on-year, and so the resulting need for finishing this output has also grown. In addition to this is the increasing numbers of sign-makers bringing the manufacture of both flat and built-up letter in-house as digital automation brings down barriers to entry on the skills front. The continuous development of wide-format print technology and the boom in demand for its output more than a decade ago has resulted in most sign-makers owning their own printer. And as the range of entry-level routing technology continues to grow in sophistication and come down in relative price, it seems a future where such equipment is standard in every sign business is not that far-fetched.

Your text here...