Laser cutters have come a long way since James Bond was at the end of one

Not since Goldfinger was set to chop 007 James Bond in half have developments in laser cutting been so exciting.

You might think that is an exaggeration, but with the growth in soft signage, the particular benefits of a laser versus a knife or other tool to cut are becoming ever more important in the sign industry.

The particular benefits of a laser versus a knife or other tool are becoming ever more important in the sign industry”

The trend for the increasing use of textile was a key theme at the recent Sign and Digital UK, with the show having served as a launch platform for various new laser cutting machines—including a couple both designed and manufactured in Britain—plus one or two others that have recently been garnering attention.

Shining bright

One such product is the new Matic Helios, which is available through Atech. Named after the sun god Helios, the device has been specifically designed to save time and reduce costs for sign companies producing large- and grand-format print.

Like most of the Matic products tailored for the textile market, the Helios enables an optimum use of printed fabrics by avoiding problems of shrinkage and frayed fabrics

Like most of the Matic products tailored for the textile market, it enables an optimum use of printed fabrics, including soft signage, flag, mesh, knitted textiles, satin and so on, by avoiding problems of shrinkage and frayed textiles as well as potential manual measurements issues.

Atech managing director, Allan Ashman says that with the Helios, the user does not have to calculate anything to do with material shrinkage.

Ashman comments: “The over head projection system of Matic’s Helios laser cutter is unique and eliminates the operator’s need to calculate for any shrink, stretch or deformation of the fabric during the printing process. The exact size of the cutpath is projected down over the printed image, the operator has the option to reposition the outline before the low wattage laser cuts and seals the textile to the exact size without burning the edges. It’s easy to use, fast, safe to use and 100 percent precise.”

With its 3500 x 8000 mm cut bed, Helios claims to offer the largest flat cutting area on the market. It also has a special textile feeding device and a driven unwinding unit to eliminate any stretch or stress on the material when pulling it off the printed roll. The entire machine is controlled by a very powerful, but simple to use, open interface computer that can work from multiple inputs.

The 70w laser is air cooled, offering great productivity and effectiveness in terms of power and cutting speed results, and a long lifetime use.

Cutting to the point

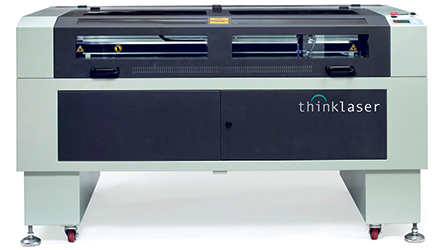

Meanwhile, the flatbed laser cutting and engraving Lightblade range has been designed by ThinkLaser, a British company based in Reigate. The range was launched earlier this year, and the company says it has been ‘inundated’ with enquiries since exhibiting at Sign and Digital.

ThinkLaser business development manager, Carol Wilson, says that the competitive price point and high performance quality make laser systems affordable and ideal for sign and display companies.

Certainly laser systems are versatile and are able to cut and engrave a range of materials including wood, Perspex, veneer, leather, fabric, and glass. In addition, all of the Lightblade laser machines are provided with Think-laser’s training and technical support and maintenance packages as well as extended warranty options from two to four years.

O Factoid: The first laser was built by Theodore Maiman. It was first used on 16th May 1960 at the Hughes Research Laboratory in California, by shining a high-power flash lamp on a ruby rod with silver-coated surfaces. O

The Lightblade comes in four models—the 3040, 6090, 1290 and 1490—all of which include closed loop water cooling for the laser tube, which creates higher stability laser output and extends tube life, an air fan to assist the cutting process resulting in higher edge quality and cleaner cutting, X and Y axis control DC servo motors which provide higher accuracy of beam positioning and better curvature resolution, and tables with motorised Z axis auto-focus, which eliminates any changes to material thickness automatically.

Lightblade is a dedicated laser cut offering from ThinkLaser, one of the growing number of British manufacturers servicing the sign and display market

The Lightblade is a high specification British manufactured laser machine and when combined with the training, technical support and maintenance packages that the company offers, it represents one of the better offerings in the marketplace today.

Versatile machinery

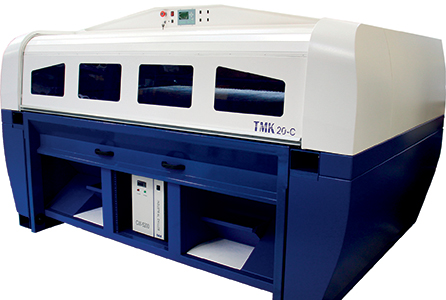

Elsewhere, the TMK20, which also launched at Sign and Digital UK, is the bigger brother of the TMK15 laser machine and is available from CTR, another British designer and manufacturer of laser cutting and engraving machines.

The TMK20 has a work area of 2000 x 1450mm and comes with laser power options of 30w-400w RF or 80W-100W DC

The company offers a range of laser machines, designed for cutting and engraving a wide range of materials, including acrylics, woods, paper and card, fabrics and even some thin sheet metals are possible with the higher power RFCO2 lasers.

The floor-standing TMK15 and 20 are powerful, large, versatile machines and ideal for those who need a large work area for both cutting and engraving, with higher power for faster processing.

The TMK20 has a work area of 2000 x 1450mm and comes with laser power options of 30W-400W RF or 80W-100W DC. It also has a minimum of twelve months warranty for the laser machine and tube, an air assist pump, and a sealed electronic water cooling unit or air cooling system, dependant on laser type.

Dedicated vs. modular

Having only covered a few of the dedicated laser cutters on the market, there are others, but you need to look hard for them. A lot of them are tailored for specific markets and one or two can be difficult to get hold of. But some of the more traditional sign and display cutter manufacturers have now incorporated laser ‘modules’ into their existing ranges so I thought it would be a good idea to compare these also in more detail for a rounded view.

Alex White, managing director of Blackman and White, which manufactures the modular Versa Tech, argues that the versatility of the modular cutter coupled with the 100w spec of the laser offers sign-makers a cost effective and highly productive finishing solution.

Blackman and White, a British engineering and manufacturer company, says that the Versa Tech offers the ultimate in tool versatility and accuracy, with crease, kiss cut, router, drag knife, oscillating knife, and driven rotary knife and laser all available on a single conveyorised or flatbed heavy-duty table.

The Versa Tech cutter offers flexibility in their modular system, the laser module was added recently to address the growing need to cut textiles in the sign market

Customers can purchase one tool initially, then add others over time to meet increasingly varied production needs and spread the cost. Dual driven tooling with interchangeable ‘drop-in’ tools, both oscillating head and driven wheel, allows for easy and quick change of cutting technique.

The Versa Tech is able to cut widths up to 3.2m, and to carry out long production runs on heavy-duty materials such as acrylics and DIBOND, thanks to the addition of a 2.5kW water-cooled router. The 100w laser is an invaluable option for textile cutting.

It offers high-precision, top quality output with a fast return on investment. The machine runs on a linear rack, keeping costs down as no belt replacement is needed, and ensuring accuracy is maintained over time.

White comments: “The Versa Tech brings the unique opportunity to allow multiple tool configuration without compromise. The conveyor solution for both laser cutting of textile print and the simple switch to the knife and router tooling allows a company to process the complete spectrum of sign and print media.

“Whilst it is clear that the growth in the printed textile market continues to exceed expectation there is often the concern for a company investing in the new technology that to justify the investment the machine should be able to act as a backup to existing cutting devices so the purchase of a laser only device could not be justified.”

White also noted that the laser option has encouraged customers who were considering alternative solutions to invest in the Blackman and White solution simply because it makes sound financial sense to have multiple facilities on the single machine.

It is becoming increasing important for a print company to be able to offer solutions across the entire range so as not to miss out”

White explains: “The opportunity fabric printing offers to a company is the ability to grow the business and create a larger customer base, where often a single large contract will include multiple print media solutions. It is becoming increasing important for a print company to be able to offer solutions across the entire range so as not to miss out.”

Combing the market

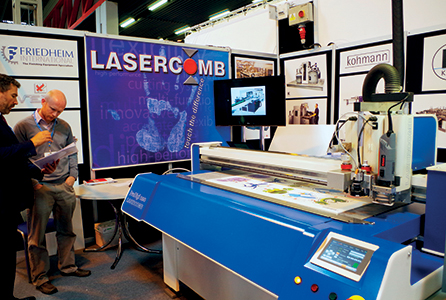

Also seen for the first time in the UK at Sign and Digital UK 2015, was the Lasercomb ProDigi NEO 2517 large format multi-functional digital cutting system. It is one of a range of machines specifically developed by Lasercomb for the high demands of the signage, display and packaging industries.

(Above & below) The Lasercomb ProDigi NEO 2517 large-format multi-functional digital cutting system was shown for the first time at Sign and Digital UK this year

Similar to Blackman and White’s offering, a modular tool concept is a key feature of the ProDigi NEO multi-functional digital cutting system, and the machine features three tangentially controlled tool holders that are capable of handling up to seven different tools, all of which can be quickly changed over as required. The alternative tools include cutting/creasing/drawing units and a 3D milling unit.

According to distributor Friedheim International, with head movement speeds of up to 100 metres per minute and built-in bed conveyor, increased productivity is assured. The new NEO also includes divided vacuum sections with electronic adjustment, automatic digital compensation of table flatness, digitally controlled Z-axis, data transfer via network (RJ45), and full digital drive. In addition, the NEO is suitable for use in an office environment as no compressed air is required, and the table is therefore near silent in operation.

Also available from Lasercomb is the ProDigi range, again specifically developed for the signage, display and packaging industries. There are currently six different ProDigi models, capable of handling sizes from a minimum 800 x 1300 mm up to 5500 x 2500 mm, and production speed is up to 100 m/min.

So, laser cutters have come a long way since the prototypes that Messrs Broccoli imagined in the James Bond movies. They are no less impressive however when you watch them in action. One cannot help but think that in the 50-something years since laser cutting was first used, they have found multiple uses but still with the development of new markets and technology that they still have a way to go.

But I think you will agree laser cutters today cut faster than Gold-finger’s flat bed version, and are more precise than Odd Job’s complementary, but still deadly, flying bowler hat...

Trotec punches into new class

One of the strongest players in the laser cutting technology sector is Trotec, which now boasts that it has a significant footprint in more than 90 countries worldwide.

Indeed its Guildford offices were one of the latest sites to be expanded and now houses the largest display of lasers assembled in the region. One of the flagship systems on show is the Speedy 500, which has a large work area of 1,245 x 712mm and features Trotec’s i-Cut camera registration system and a unique multifunctional table concept—allowing it to be optimally configured for all applications. In addition it has a pass-through function, enabling the flatbed laser to process work pieces larger than the work area.

The SP1500 spells a new technology dawn for Trotec

The latest development to come out of the company is a big step up for it and sees the launch of the SP1500, its largest and most powerful cutter to date. Designed with sign-makers and stone engravers in mind, this CO2 laser cutter (185 (h) x 1500 x 1250mm working area) features a 400 watt laser and can cut through thick acrylic, wood and plastic and has a robust flatbed that can handle large plates and sheet material. With the addition of the heavy load table, the SP1500 can process objects up to 50kg in weight, perfect for granite plates, marble tiles and even tombstones.

Your text here...